Sample Firing Schedule

• Tuesday-Thursday: GLAZING & WADDING

• Thursday-Friday: LOADING THE KILN

• Friday Evening @ 8PM: LIGHT THE KILN & BEGIN WARMING

• Friday Night – Sunday Morning: STOKING SHIFTS

• Sunday Morning: CLOSE UP THE KILN

• Following Friday: UNLOAD KILN & CLEAN UP

How It Works

PRE-FIRING:

Help is always needed to split and stack wood and prepare the kiln for the upcoming firing. Work shifts can be arranged with based on the current needs and the individual’s availability and skills.

GLAZING, WADDING AND OTHER PREP:

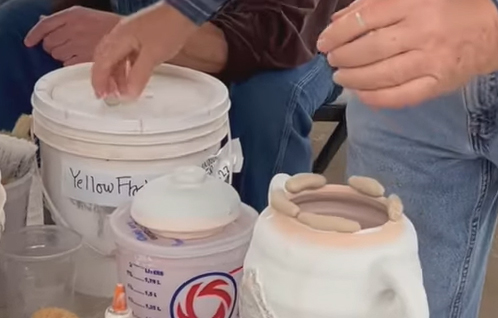

During the week leading up to the firing (Tuesday-Thursday), glazes and wadding will be available at the kiln site. Artists can drop by at any time convenient to them, day or night. For those that are firing for the first time at FireSong, it may be ideal to come by during the afternoon/early evening when the bulk of artists are glazing, so they can provide knowledge about the glazes and tips for FireSong specifically. Learn more about the glazes we offer at FireSong.

All work must be wadded prior to loading into the kiln. Learn about wadding.

LOADING THE KILN:

It is said that loading an anagama kiln is the most difficult part of the firing. The placement of pieces within the kiln distrinctively affects the pottery’s appearance, as pieces closer to the firebox may receive heavy coats of ash or even be immersed in embers, while others deeper in the kiln may only be softly touched by ash effects. The potter must imagine the flame path as it rushes through the kiln and use this sense to ‘paint the pieces with fire.’

At Firesong, we begin loading the kiln with the Salt section (back 1/3 of the kiln) usually on a Thursday afternoon. Anything you would like in the salt section, must be glazed/wadded and ready to load by Noon on Thursday. The rest of the kiln is loaded beginning around 10AM on Friday morning.

Everyone is involved in the loading process in some way. 2-3 people work inside the kiln to place work on the shelves. Everyone else helps to transport work from the glazes shelves to the kiln at the direction of those doing the loading. As work is loaded and shelves are emptied, we begin the clean-up stage to help cut some time off the end of the day.

Once loaded, a fire is built in the chimney and front fire box, but not lit yet. Then the the door is bricked up, strategically leaving air inlets at the bottom of the door and a larger opening midway up the door which will later serve as a stoke hole for feeding wood into the firebox.

Once the door is bricked up, we do a quick clean up in preparation of firing. The entire process lasts until about 6PM.

FIRING THE KILN:

The initial fire is lit in the chimney and fire box around 8PM on Friday night and a small campfire is maintained overnight to warm the kiln and pots.

Around 8AM Saturday morning is when the excitement begins and we truly starting firing up the kiln. Stoking occurs around the clock until a variety of variables are achieved including the way the fired pots look inside the kiln, the temperature reached and sustained, the amount of ash applied, the wetness of the walls and the pots, etc.

Pyrometric cones are used to determine when the kiln has reached the targeted temperatures. They are placed throughout the kiln in front of spy holes and on the front wall. They melt as the temperature rises, letting us know wen the glazes have had time to thoroughly mature.

The length of an anagama firing is dependent on many factors and can take anywhere from 48 hours to 12 days. At Firesong, we generally finish early Sunday morning, between 6AM & 10AM.

Once we reach the end of the stoking cycle, the stoke holes are bricked up and sealed. The kiln is then left to cool for a full week.

UNLOADING THE KILN:

The kiln needs about a week to cool before we are able to unload. Unloading is generally scheduled for the Friday following the firing (occasionally on Saturday depending on availability). Unloading begins at 10AM. To door is unbricked, remaining ash is shovelled out and then work is carefully unloaded. Working in assembly-line fashion, pieces are passed from the kiln to the tables/shelves and organized based on where they were located in the kiln. Once fully unloaded, we take a break to view all of the work, discuss what worked and what didn’t, ask questions and review the firing as a whole.

CLEAN-UP:

After the kiln is unloaded and work admired, it is time to work again. Everything must be cleaned and readied for he next firing. Shelves are scraped and kiln wash applied. Bricks are cleaned and stacked. Tables must be washed. Trash removed. Glazes and tools packed up.

We also use this time to re-stock our wood carts. Split fresh wood to be seasoned and organize the kiln shed in general.

Not until all the clean-up is done, is the firing considered complete.

FOLLOW-UP:

After you get home and have a chance to clean-up and get a good look at your work, we ask that you take a few photos of your favorite and/or most iconic pieces from the firing and post them to our Cluster account. This allows us to keep a visual record of past firings.